|

| Typical Multipass Test Stand from GMNi |

With an initial efficiency at 4 micron of >99.5% required to meet the EURO 6 emissions requirements, the particle counter has to work harder than ever to accurately count the downstream particles. As 4 microns is the limit of the current ISO approved technology we face an increasing level of experimental error in media measurements which is exacerbated by the fact that customers also ask for initial efficiency not overall efficiency.

Initial efficiency in ISO 19438 is measured over a period of only 3 minutes during the entire test (4-6 minutes) at which point the particle counts are increasing as the contaminant concentration in the test circuit increases from zero. The result is that the data is prone to significant errors at 4 microns for both initial and overall efficiency (see plot below for a typical cellulose meltblown composite) tested 7 times on the same lot of material to enable a level of inherent variability to be established.

|

| Inherent variability in overall efficiency for a typical flatsheet fuel media. |

As you can clearly see, the level of inherent variability grows significantly as we approach 4 microns. This can only be expected of such a system operating at the edge of the measurement range.

The key challenge therefore is to move the measurement goalposts. This is easier said than done but the market leaders in OPC technology, PAMAS, have introduced the latest in technology, known as SLS. Instead of operating with a 4-40 micron range OPC, the new technology operates with a 1.5 to 20 micron range OPC.

The impact though in terms of multipass design is significant:

- the cleanliness level in the test circuit has to be significantly improved thus requiring hydraulic filters with a Beta 1000 or 2000 level of efficiency of around 2-3 microns.

- The OPC upstream and downstream of the sample has to have a significantly lower concentration of dust and a much higher dilution is required.

One other major issue is that the particle sizes are now outside of the ISO official range (i.e. they lie less than 4 microns) and so any test is not according to the standard which leaves companies scratching their heads. The solution is to have both technologies on the same test stand so that the test stand still abides with the ISO standard but has extended capability (i.e. two sets of particle counters!).

The benefit of the new OPC technology is that it moves the 4 micron initial efficiency to the middle of the calibration curve (not the edge) and we can also start to look at 2 and 3 micron efficiencies that are naturally much lower than 4 microns and therefore a better discrimination in performance between media can be made. This is shown in a graph from a SAE presentation made by Ahlstrom on this technology.

|

| Fractional Efficiency of various media using SLS Technology. |

The graph shows 5 grades tested using SLS technology. If we use the 4 microns as the cut off point we see that there is a little difference between the samples in terms of performance. However by extending the range to a lower particle size the different media perform significantly differently allowing a more educated analysis to be undertaken of the different media in terms of their relative performance.

Does SLS Technology measure identically to standard OPCs?

We undertook a study on a test stand with two OPCs fitted on a Euro 6 level media to see what the resultant performance looks like. The result was very consistent across a range of grades. The new OPC shows a significantly lower initial efficiency than the standard OPC (see below).

|

| SLS and standard OPC initial efficiency performance on a Euro 6 media |

Why the discrepancy? There are only two possible reasons;

1. the OPC's are operating differently or

2. the media performance is "different" in some way from sample to sample.

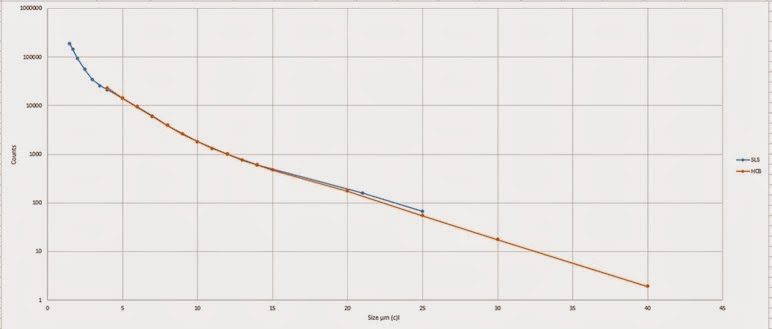

To look at point 1 we took the media out and looked at the particle counts of a pre-dosed test system (oil with a known amount of ISO medium test dust) and looked at the particle counts from both particle counters.

|

| Particle counts with no media of both HCB and SLS Particle counters |

The number of particle counts are aligned extremely well in the overlapping range of 4 to 20 microns which would clearly exclude point 1 as a reason for the discrepancy.

The theory currently is that the new OPC is detecting particles in the fluid downstream that the traditional technology can't. In this case the belief was that synthetic particles were being dislodged downstream from the media and were being detected in a way that the older HCB technology couldn't detect.

So there you have it, there is a new technical opportunity to extend the efficiency range of fuel media being driven by a new capability to measure it. This technology not only extends the measuring range, it increases the precision of measurement and has an ability to identify particles that the current technology can't "see".

The jury is still out on whether this technology will become mainstream plus the ISO committee with the 2003 standard is way behind the technology developments here. But there are test stands out there able to undertake this and it will not be long before we start seeing specifications at 2-3 microns being set by element manufacturers.

Thanks a lot for reading and have fun.

Tony

No comments:

Post a Comment