The filters that these facts refer to are the traditional bag or pleated filter elements that make up the many air handling units in buildings world wide.

The huge amount of energy dominates the total cost of operating such a filter. A presentation made by Freudenberg at Filtrex Asia in 2011 attempted to quantify the total cost of ownership of a filter:

- 70-80% of a filter's cost is in the power needed to maintain the element over it's lifetime

- 20-30% lie in the purchase, installation and end of life disposal costs of a filter.

in short the real cost of a filter is not in the material but in its operational lifetime in terms of kWh. As we have seen in other blogs this comes down to the resistance of the filter to airflow (pressure drop). If we increase the airflow resistance through higher efficiency this increases the air resistance and the power required by the fan to pull the required airflow through the filter. However as we have also seen, not all filters are created equal. A poor filter media or element design may have a negative impact on the pressure drop for a given level of efficiency.

A second consideration is the element lifetime. All elements have recommended terminal pressure drops at which the element should be replaced. This is dictated by the environmental location of the duct so, for instance, in Shanghai we would expect to see a highly polluted atmosphere with high soot levels whilst in Saudi Arabia we would expect to see more natural dust. Both atmospheres will affect both the lifetime and selection of filter for the air handling unit (AHU) in a different way. However both scenarios have one thing in common, as the element is loaded, the amount of power required to maintain the airflow will increase and the cost of operation will increase in line with this. At some point, the cost of operation will make the replacement of the filter economically desirable.

In the same paper Freudenberg showed this very succinctly. Reducing the pressure drop across a filter at the same efficiency extends both the lifetime and reduces the energy costs.

|

| Effects of dP on lifetime and energy usage of a typical bag filter (Freudenberg, Energy Efficiency in Air Filtration, Filtrex Asia, New Delhi, December 2011) |

At the same conference, Sandler presented a similar paper where they showed how the replacement point in terms of pressure drop of the filter can affect the overall costs of the filter unit.

|

| Total cost of ownership as a function of replacement pressure drop of the element (Sandler, "Optimising Life Cycle Costs with new Synthetic Pocket Filter Media", Filtrex Asia December 2011") |

However the energy consumption is rising all the time (light blue dotted line) and the total cost of of ownership (dark blue solid line) of the filters reaches a minimum before the cost of operating the element starts to rise.

In short there is an optimal replacement point for any element beyond which the real cost becomes uneconomic.

This is a good academic exercise used by both companies to promote their latest and best technology. The reality of life is that most people rarely notice the filters or air conditioning let alone prioritise the service intervals for replacing a filter. This was highlighted in an excellent blog by Ken Bloom in 2004 . He highlighted the following reasons for HVAC monitoring:

- Reliably clean air is a resource not unlike water and power.

- Accurate monitoring eliminates the guesswork of knowing when to replace air filters

- Proper replacement reduces material and labor costs to monitor detect and maintain the filtration system.

- The automated air filtration system affords greater environmental control eliminating HV AC failure and plant disruptions.

- Air filtration monitoring reduces energy consumption when filters are changed "on time" eliminating drag on HVAC system.

- Air filtration monitoring can assist in reducing energy consumption when higher efficiency filters are used to keep heat exchange elements clean.

Operating a filter beyond its optimal lifetime endpoint is costing money and reducing performance. A single element in a AHU could be using up to 500kWh per annum (Freudenberg, Filtrex Asia 2011) than a poor performing filter of the same efficiency. In a bank of 10 elements that is a significant amount of power consumption.

So how can we tell optimal lifetimes? One way is by monitoring the actual performance in real life with a range of mobile phone applications that enable you to track the live pressure drop of a filter and can set alarms for replacement.

However the best way of improving the cost effectiveness of a filter is to start off with a low pressure drop filter in the first place. As we have seen, a low initial pressure drop gives a huge advantage in terms of overall costs, more than covering the higher purchase price.

The Eurovent ratings are a measure of the power consumption of a filter over its lifetime and from this a determination of a rating for the filter can be given in the form of a label attached to the filter cartridge.

|

| Typical Eurovent 4/11: 2014 energy label for a F9 filter (AAF) |

Eurovent are an industry standards committee set up to set the standards for air conditioning and refrigeration systems in buildings and, as the name suggests, work on developing and implementing industry wide standards to be applied across the EU.

Eurovent ratings are calculated based on the shape of the loading curve during the EN779:2012 test at 3400m3/hour.

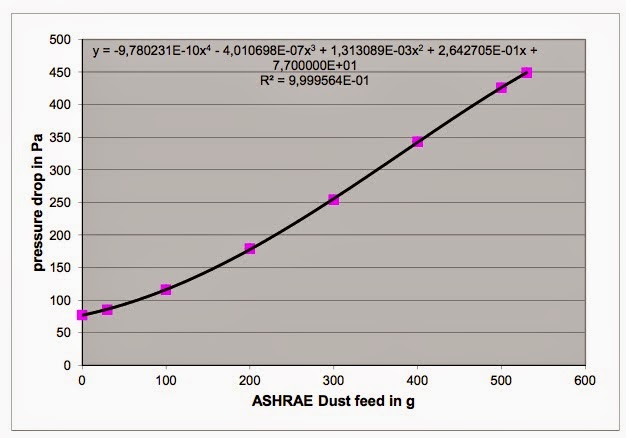

|

| EN779 loading curve with a polynomial best fit equation applied |

The shape of the curve allows for a 4th power polynomial equation to be fitted:

to be fitted to the data and from this a range of constants, a, b, c, d and e are extracted. e is the initial dP of the element with no loading.

From this a measure of the average pressure drop for the loading can be calculated from the following equation:

The constant Mx comes from the filtration rating of the element given below

Knowing the average pressure drop we can now calculate the power consumption using the following equation:

where qv is the flow rate of 0.944m3/s, t is the operational running time of 6000 hours and n = 0.5.

Based on the power consumption we are now able to apply a rating using the following table

There are several notes.

- The 2014 ratings replace the ratings previously issued in 2010 covering a wider range of ratings A-G.

- The rating has to be undertaken based on a loading undertaken at a flow rate of 0.944m3/s (3400m3/hour)

- The DHC must be > the M minimum capacity

Summary

In summary energy consumption is a critical requirement for HVAC filtration making up 80% of the total cost of a filter installation and is often overlooked when installing an air handling system. There are several issues that the user needs to account for:- optimal balance between element cost and energy

- monitoring the element pressure drop in service to ensure that the optimal replacement intervals are selected.

- element power consumption as measured to Eurovent 4/11 2014 allowing for an

Thank you for following me. Please feel free to contact me if you have any further questions.

Have fun...

this blog is amazingly managed for Eurovent Air Handling Unit, i would like to say one more thing that i have visit its website which was really good.

ReplyDeleteYou must practice patience and avoid running to replace any parts since the first heater repairman who came to your house says so. While it's true that things don't last forever, there are millions of homeowners who spend money unnecessarily as a result of dishonest or even incorrect diagnoses simply because the technician said a part cannot be repaired and must be replaced. Emergency AC Repair Toronto

ReplyDelete