In order to add performance we need to revisit the basics of how filter materials are manufactured and how contamination is captured. Any process for laying down non-woven fibres creates a density gradient from top to bottom meaning that the fibres are more open at the top (upstream) side of the filter material than at the bottom. The result is that the pore size at the bottom is smaller creating in effect a cone into which the contaminant falls. I've illustrated this in a very simple way below.

|

| Simplistic view of the pore structure of a filter |

Gradient density structures in filtration are designed to control this process better. They all into two categories:

- homogenous gradient density structures formed at the same time with the same materials

- composite layered structures of multiple materials

|

| Simplistic gradient density filtration structure |

The downside of this is that the media thickness has significantly increased meaning that there is less media that can be squeezed into a standard pleated element. This therefore reduces surface area and increases face velocity with the impact on DHC and efficiency previously mentioned in my blog of yesterday. The key therefore of any gradient density structures lies in adding a more open upstream side without increasing thickness significantly. This requires different fibres than on the downstream side which leads to more complex product developments.

I will give you some examples of each of the product strategies.

Homogeneous Gradient Density Structures- Capaceon Technology

Capaceon filter media technology from Hollingsworth and Vose is an excellent example of controlled z-directional structures. The basic material is 100% cellulose and the key to its design lies in a proprietary process that creates a two layer structure in the forming process on the paper machine with defined permeability in each stage. The result, in terms of performance is a significant improvement in media Dust Holding Capacity at any efficiency rating across the permeability range in air filters.

|

| Capaceon performance enhancement in air filter applications over traditional single layer materials |

As pointed out above the media suffers from a slight increase in thickness (about 10%) compared to standard media and in order to ensure that the benefits are seen in the final element, the end user has to optimise the filter element design with slightly fewer pleats and slightly higher face velocity.

This technology is excellent for air filtration but suffers in liquid filtration as the more open top layer is compressed in the higher viscosity and pressure drops of liquid filtration applications.

Composite Technology

Composite technology creates a gradient density structure through multiple layers of media. The idea has been well known for many years and is used daily in media and element manufacturers through composite lamination or co-pleating different materials.

One of the most basic example of this is the cellulose/meltblown or cellulose/synthetic (including electrospinning) technology where a standard cellulose filter media has an enhanced performance through the addition of a synthetic top layer. The top layer acts to disrupt the filter cake and adds significant capacity to the media. The advantage of meltblown (and even more with electrospun fibres) is that the fibre diameters are significantly lower than with cellulose so a high level of fibre density can be created with limited increase in thickness and, more critically, pressure drop.

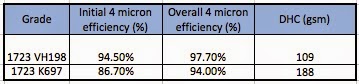

To illustrate this I have taken multipass data for a typical 180gsm modern diesel grade, 1723 VH198, manufactured by Hollingsworth and Vose and compared it to the same grade with a 50 gsm PBT meltblown, 1723 K697.

|

| Multipass performance of cellulose filter media v cellulose meltblown composite |

This is not just restricted to fuel media. Performance enhancements by adding very fine fibres such as electrospun, nanometre diameter fibres can significantly increase the performance of pulse clean gas turbine elements in air filtration. The recent move in this market to achieve F8 or F9 efficiency ratings can't be achieved using the traditional cellulose+ PES single layer material. The best efficiency that we saw was a significantly lower M6 efficiency rating. Through the addition of a meltblown layer (typically 10gsm of PP), this rating can be significantly improved to F8 or even F9. Some companies, such as Donaldson, use their own proprietary electrospinning technology to achieve this level of performance.

The Composite Future

The concept of composite filter media is moving from the specialty markets to the mainstream as end users look to increase performance advantages over their competitors or as performance specifications increase.

Dual layer composites are no longer the norm with composite materials up to 5 or 7 layers under development for fuel applications with huge lifetimes at exceptional efficiencies (>99.6% initial efficiency at 4 microns).

The limiting factor of the efficiency of the cellulose layer is going to be replaced by the simple expedient of an open cellulose layer, with the main efficiency layers being the synthetic layers bonded to the cellulose. This turns the cellulose from being the efficiency layer to being a pleatable backer enabling processing on standard pleating lines.

The synthetic media itself will be extended further with finer and finer fibres being manufactured to a more consistent level at higher and higher throughput. This will require further advances in meltblown technology to achieve but the technology is slowly evolving in that direction.

Thanks for reading this blog. If you have enjoyed it or have further topics to discuss please feel free to contact me.

Tony

No comments:

Post a Comment