Media suppliers are under increasing pressure to differentiate themselves from their competition. They work tirelessly to develop an optimised system with improve efficiency, lower pressure drop or longer lifetimes. The element manufacturers in turn work extremely hard on achieving the same goal in an element format, whilst at the same time also trying to ensure, in the competitive markets that they serve, that the overall cost (of either the element) or its total inservice cost (power consumption, lifetime) are competitive.

The real challenge for both parties is to be able to ensure that what is promised by the media supplier can achieve the same level of performance in the final element. The reality is that there is always a significant discrepancy between flatsheets and elements in any filtration system.

The simplest reason for the discrepancy lies in simple geometry. A flatsheet test always presents the media at the optimal angle to the airflow (perpendicular), has no dead zones or turbulent flow of air. In real life the media is pleated or shaped in someway to maximise surface area and decrease face velocity. There are many element designs but the important issue is that the air and the contaminant are now channelled into a narrow gap, often in a turbulent way and then have to pass through the media at an oblique angle.

The result is inevitably the following changes:

- higher pressure drop at a given face velocity

- lower material lifetime (as measured in dust holding capacity) versus a flatsheet.

This is where the element designer makes his money. The secret to good element design lies in minimising the effects of loss of media area and ensuring good pleat or bag separation to ensure even air or liquid flow through the element.

The media can affect this in some ways- for instance thicker media reducing the space between pleats but, in general, this is less critical.

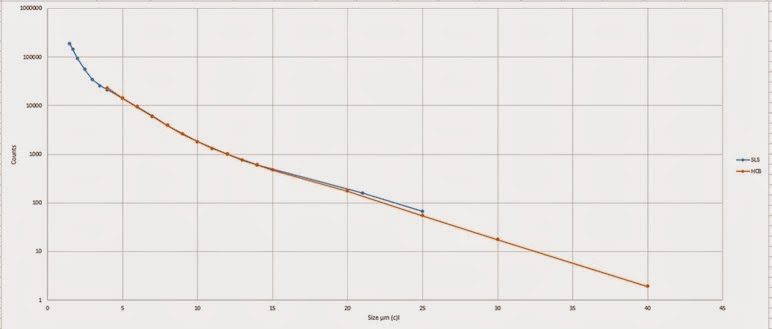

In trying to clarify this better, I undertook a study looking at the differences between flatsheets and elements from F7 to F9 rating to EN779:2002. The tests were undertaken at the same face velocity of 12.7cm/s and the testing was carried out on two test stands, a standard EN779 test stand and a flatsheet test stand configured to run with EN779. The test dusts used were different. The element testing was undertaken with ASHRAE 52.1 test dust and the flatsheet testing was undertaken with SAE ISO Fine test dust. Both of these were clearly confounding factors but in reality all we wanted to achieve was an assessment of the offset between both test stands and between flatsheets and elements.

The key to any offset analysis is to ensure that the data is taken at the same time on each test stand. In this case we can use the inferred data at 250, 350 and 450 Pa as our reference points. What this gives is 3 offset points per sample for both capacity and 0.4 micron efficiency.

Looking at the data we can see that there is a good offset for both properties